When designing a heating and hot water system you would first calculate the heat losses from the building along with the demand for hot water. Insulation levels in new properties are designed to much higher standards which in turn lowers the heating requirements and hence the carbon footprint of the building. It is often possible to upgrade the thermal insulation of existing properties which is the first port of call when considering a new heating system.

A heating and hot water system is designed with the calculation based on the worst case scenario, that is, full demand on the system with an outside air temperature of approximately minus 2 degrees centigrade. However, these conditions only prevail on perhaps 8 days a year and for the rest of the time a large capacity boiler is not working efficiently.

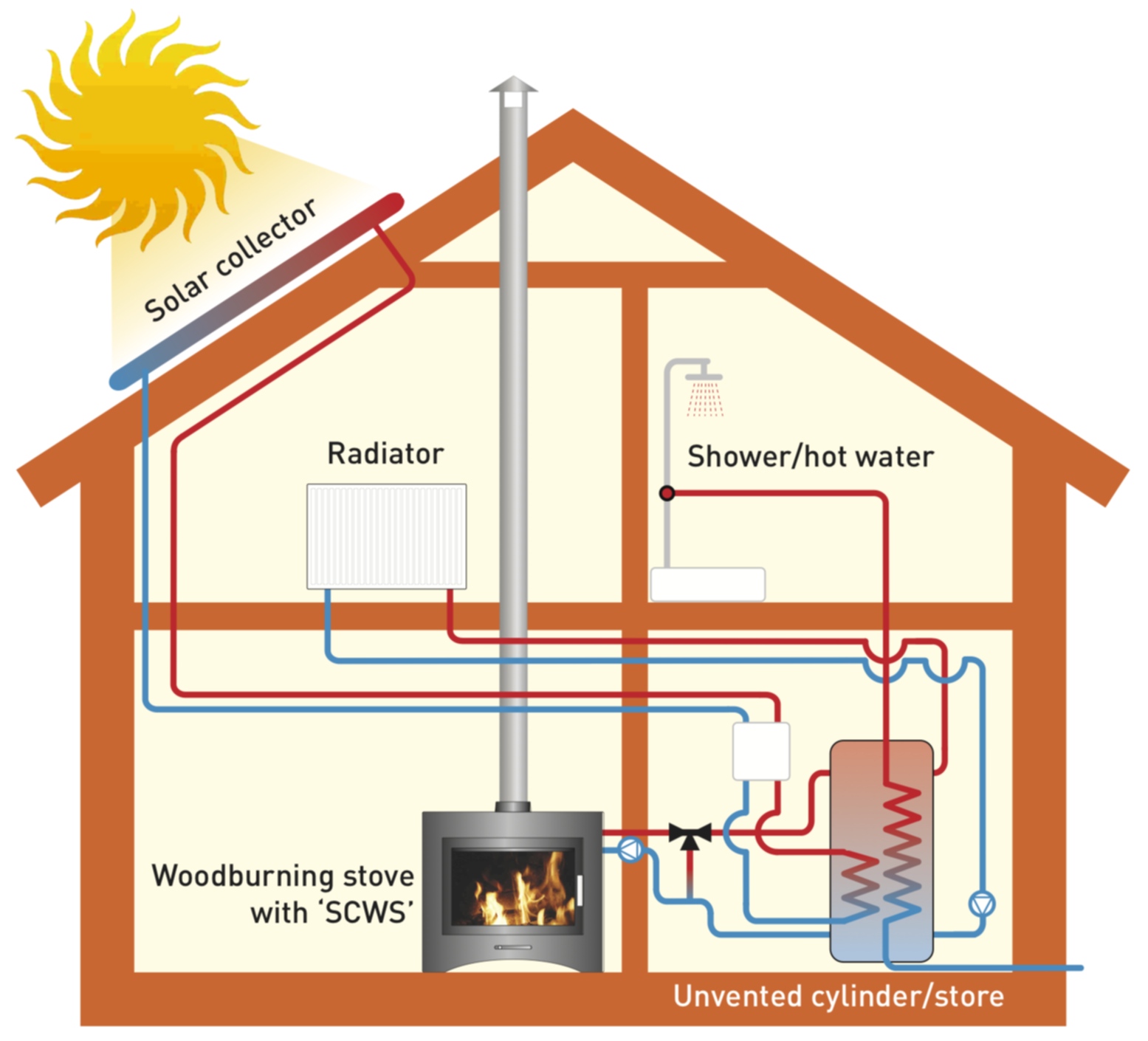

Combined heating and hot water systems involve using two or more different heat sources, using the lowest carbon source first and gradually adding heat until the total required output is obtained. For example, solar thermal panels can provide most of the domestic hot water requirements for a family home throughout the summer months with barely a sign of a carbon footprint. These panels may produce 3 kW’s or more and can be backed up by a heat pump or traditional boiler for the remainder of the year.

If a wood burning stove with a back boiler is added to the system, this can contribute another 12 kW’s which again is carbon neutral heat source and would probably provide sufficient heat for most of the year.

In times of severe weather or when the stove is not lit, then the system can be backed up with an air source heat pump or condensing gas or oil boiler. An air source heat pump is an extremely efficient way of producing hot water for both domestic use and central heating.

Obviously, a condensing gas or oil boiler will not be eligible for RHI but with up to 94% efficiency, push button convenience and limited use, they may prove valuable to the overall system design.

All these combined heating inputs can be teamed up with both radiator or under-floor heating systems and various designs of hot water storage. Control of the system is of the utmost importance to gain the maximum efficiency and lowest carbon footprint. Addition of weather compensation to the controls adds a further sophistication.

With modern underfloor heating systems you have complete room temperature control. There are no cumbersome radiators occupying valuable floor space, lower fuel bills due to lower water temperatures and comfortable warmth for all your heating needs. Furthermore, warm dry floors create a hostile environment for dust mites which can cause allergic reactions and also reduce the danger of damp and condensation getting into walls. The low amount of air movement during heat transmission will also help prevent airborne dust.

Water circulates through the underfloor heating pipes at around 40C which in turn heats the floor to a surface temperature of 25 - 28C. With traditional radiator systems water is heated closer to 70C using a small surface area far hotter than the room. These systems are economical to run, virtually maintenance free and provide the most comfortable warmth consistently.

A typical ground floor installation will involve laying insulation above the original concrete slab to ensure minimal heat losses. Multi-layer composite pipe with an aluminium layer in the centre is then clipped at 150mm centres to allow a maximum transference of heat. Depending on your room layout one of our trained engineers will decide how best to lay your pipes to optimise efficiency. Either a dry or liquid screed is then laid on top of the pipes with a foam insulation strip around the edge of the room to take up any expansion and minimise heat losses. Your choice of flooring will then be laid on top of this. If your project is not a typical installation then don’t fret as there are many ways to install under floor heating, the smallest being an overlay just 16mm thick.